Let’s be honest—nobody wants to deal with a weird smell in their home. Especially one that reminds you of rotten eggs or a damp basement. If you’ve noticed an unpleasant odor hanging around, there’s a chance it could be sewer gas.

Let’s be honest—nobody wants to deal with a weird smell in their home. Especially one that reminds you of rotten eggs or a damp basement. If you’ve noticed an unpleasant odor hanging around, there’s a chance it could be sewer gas.

It’s not the most glamorous topic, but knowing how to test for sewer gas can save you a lot of trouble (and headaches—literally). Here’s what to know, what to look for, and how to fix it.

What Exactly Is Sewer Gas?

Sewer gas is a mix of gases that comes from decomposing waste in your plumbing system. One of the main culprits is hydrogen sulfide, which gives off that unmistakable rotten egg smell. But it can also include methane and ammonia—gases you definitely don’t want lingering in your home.

And while a faint odor might seem harmless, sewer gas can actually be dangerous if it builds up. That’s why it’s worth paying attention.

How to Tell If It’s Sewer Gas

Before diving into tests or calling a plumber, it helps to recognize some of the telltale signs. You might be dealing with sewer gas if you notice:

- A persistent sulfur or rotten egg smell

- Gurgling or bubbling sounds from your drains

- Drains that seem slow or frequently clog

- Headaches or nausea with no obvious cause

- The smell gets worse when it’s humid or after heavy rain

Simple Ways to Test for Sewer Gas

Here’s the good news: you can do a bit of detective work yourself before calling in the pros.

1. Run Water in Unused Drains

If you have a guest bathroom or basement drain that rarely gets used, the water in the trap can evaporate—letting gas sneak in. Just run the water for a few seconds to refill the trap.

2. Try a Soapy Water Test

For visible pipes, especially around toilets or under sinks, you can brush on a little soapy water. If you see bubbles forming, you might have a leak where gas is escaping.

3. Use a Sewer Gas Detector

There are handheld gas detectors online that can help spot levels of hydrogen sulfide or methane. They’re not perfect, but they can give you a heads-up.

4. Trust Your Nose

Seriously. If it smells off and keeps coming back, that’s a red flag—even if you can’t see anything wrong.

When to Call in a Professional

If the smell sticks around or you’re just not sure where it’s coming from, don’t stress it alone. Sewer gas isn’t just annoying—it can be a sign of cracked pipes, venting issues, or deeper problems underground.

At Action Plumbing, we specialize in sewer odor detection. Our team uses professional tools like smoke testing and pressure inspections to find the root of the problem fast—and fix it before it gets worse.

Final Thoughts

No one wants their home smelling like a sewer. But if it happens, the best thing you can do is act early. Testing for sewer gas doesn’t have to be complicated—and you’re not alone if you need backup.

Not sure what’s causing the smell? We’ve got you. Call Action Plumbing and we’ll take care of it—quick, clean, and done right.

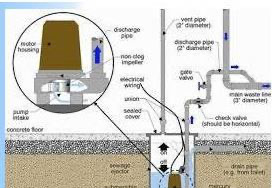

Understanding a Residential Ejector Pump System (With Diagram)

Understanding a Residential Ejector Pump System (With Diagram) When dealing with below-ground plumbing systems, such as in a basement bathroom, you may have encountered the term

When dealing with below-ground plumbing systems, such as in a basement bathroom, you may have encountered the term  Adding a bathroom in your basement can increase your home’s value and functionality. However, without proper

Adding a bathroom in your basement can increase your home’s value and functionality. However, without proper  Plumbing issues can be frustrating, especially when the cause of the problem is hidden deep within your pipes. This is where a plumbing camera, also known as a sewer camera or drain camera, comes into play. With advanced technology, plumbing cameras provide a non-invasive way to inspect your plumbing system, helping identify issues before they become costly repairs.

Plumbing issues can be frustrating, especially when the cause of the problem is hidden deep within your pipes. This is where a plumbing camera, also known as a sewer camera or drain camera, comes into play. With advanced technology, plumbing cameras provide a non-invasive way to inspect your plumbing system, helping identify issues before they become costly repairs.