WHAT IS PIPE LINING?

Pipe lining is your no-dig solution for repairing or replacing cracked, broken, leaking, or root-infested pipes. Above all, it’s important to deal with this especially with your commercial sewer lines.

As a result of it being a “no-dig” system, costly excavation and demolition are no longer necessary. This makes pipe lining less expensive than the traditional re-piping alternatives, such as excavations or open trench methods.

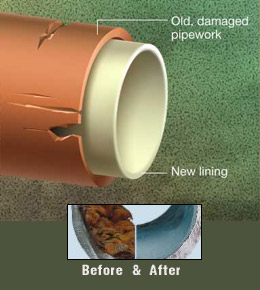

To best describe pipe lining, you’d need to image a smooth new PVC pipe installed within the existing damaged pipe. A watertight seal called an epoxy is filled in the gap between the old and new pipes. As a result, tests can show an improvement in original flow capacity despite the loss of inner diameter.

Pipe lining materials (i.e. epoxy and custom-designed PVC coated liner tube) are applied with minimal disruption to your property. However, the liner is continuous and smooth with no seams or joints.

Action Plumbing can install pipe liners much faster with minimum inconvenience and disruption in comparison to excavation. As a result, the pipe liner also eliminates serious environmental and landscape damage.

In addition, there is no damage to your trees or landscape since the liner tub travels under landscaping, sidewalks, buildings, garages, patios, swimming pools, etc.

HOW DO I KNOW IF I NEED PIPE LINING?

When you own or manage a building over 10 years old, the damage is probably in progress. Undoubtedly, you’ll experience or see symptoms of pipe corrosion which include the following:

- Water with discoloration

- Stains on sinks and/or tubs

- Odors or leaks

- Poor water flow

- Continuous sewage backups

WHAT TYPE OF LINES CAN BE LINED?

So, both residential & commercial sewer laterals & drainage pipes from the property to the main line can have lining done to them. In addition, roof drainage pipes, collectors, & commercial floor drainage pipes can also have this done to them.

WHAT CAUSES PIPE PROBLEMS?

Tree Root Infiltration: From time to time, tree roots can pierce and infiltrate drainage systems, through pipes, seams, and connections. As a result, these cause blockages and water loss.

Water: Water is able to erode, plug, corrode, weaken, and form pinhole leaks in the plumbing system over time. In like fashion, hard water full of minerals can cause your pipes to become encrusted and plugged causing blockages. Also, surface collected water and soft water has a few dissolved minerals, is acidic, and easily dissolves and thins your pipe walls.

Plumbing Materials: Unquestionably, metal plumbing systems using copper or other galvanized systems show significant problems over time. Moreover, problems can occur in as little as six years. In addition, most copper and galvanized pipes show signs of corrosion within 10 years. So, the best long-term solution to pipe corrosion is to stop the water from coming into contact with your pipe’s walls.

PIPE LINING SYSTEM CAPABILITIES:

- Drainage and sewer pipes of all types (including galvanized steel, cast/black iron, copper and lead pipes)

- Diameters from 3″ to 10″

- Lengths up to 300 FT

- Bends up to 90 degrees

- Repair all common pipe materials

- Spot repairs of joints and other structural defects

- Insertion of part or whole sections

- Blind ends

HOW DOES THE PIPE LINING PROCESS WORK?

PREPARATION: Thorough preparation of the existing pipe is necessary, in order to achieve the best results. This includes a quality video camera inspection, cleaning, and measuring the diameter and length of the pipe. Large-scale repairs may require the stoppage of water infiltration and bypassing flows in the existing pipes in order to prepare the pipe for the lining process.

INSTALLATION (INVERSION): We install the pipe liner by inserting the liner through drain clean-outs or small open entries. In case of partially damaged drain sections, we only repair the bad part of the beginning of the pipe. The liner materials are chosen depending on the pipe condition. Standard liner tubes are used for straight pipes and more flexible tubes are used for pipes with acute bends, angles, and transitions.

APPLYING THE EPOXY: The epoxy bonds the liner to the pipe wall. This bond creates an extremely tight fit to prevent water from entering or escaping the pipe. Erosion or corrosion inside of the pipe stops immediately after relining with the pipe liner system. Roots can no longer penetrate a lined pipe.

Once a pipe has been lined, it will stay free of root intrusions for the life of the pipe.

CURING PROCESS: The liner and epoxy are cured within 4 to 12 hours. Once cured, service to the pipes will be returned.

HOW CAN I SAVE MONEY?

Don’t excavate…rehabilitate! Excavations are very expensive in labor, time and material, permit fees, and damage costs.

Pipe lining does not disrupt your operations. You will not have to lose business due to hours of loud excavating equipment, mess, and sectioning off dangerous areas. Drainage operations will only cease for a minimal time.

Once the pipe lining is complete there are no signs of repair or property damage. Pipe lining can also be scheduled at night, after store closings.

Pipe lining improves the physical condition and longevity of your system. This process stops corrosion, roots infestation, and improves flow capacity.

If you’re interested in our pipe lining services in Philadelphia, King of Prussia, West Chester, or anywhere in New Jersey, don’t hesitate to contact Action Plumbing today to find out more.